Everything You Need to Know

Deadbolts on Gates

Overview

Info You Need to Choose Your Deadbolt

So what to do when you have a thick gate?

We offer extended deadbolts for gates up to 3-3/4″ thick – this is a single cylinder deadbolt.

Currently there is no extended deadbolt for a double cylinder application.

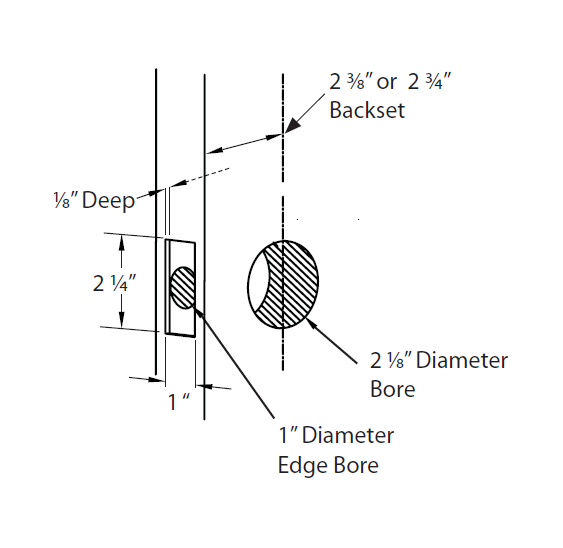

Creating a pocket to take away gate thickness for a double cylinder deadbolt to fit.

What if you have a thick gate and need a double cylinder?

The only thing to do is to ‘take away’ thickness from the gate – create a pocket on each side of the gate so that you ‘nest’ the deadbolt plates in there. For example, your gate thickness is 3″. The double cylinder deadbolt you’ve chosen will allow a maximum thickness of 2-1/4″. The difference between those two figures is 3/4″. You’ll need to take away 3/4″ from your gate thickness by creating a pocket on each side that is 3/8″.

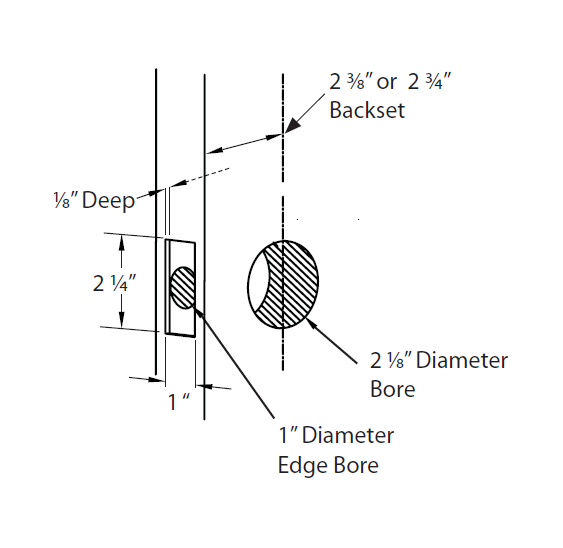

the basics of installation

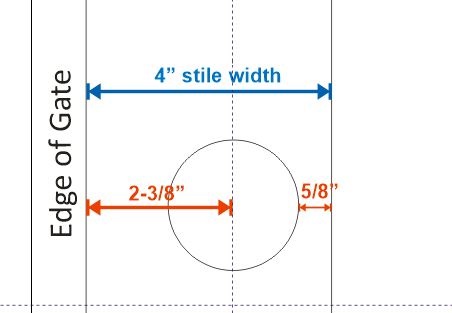

In order to install a deadbolt, you need to bore a 2-1/8″ diameter hole through the gate. The centerpoint of that hole will be at either 2-3/8″ or 2-3/4″ from the edge of the gate. You’ll also need to make an edge bore for the bolt to fit through.

Most Popular Deadbolts

Important Factors to Consider

Stile Width

With a maximum gap of 1/2″, that leaves 1/2″ of the bolt to be engaged in the strike plate. The ideal gap is more like 1/4″ to 3/8″, which provides for even more engagement of the bolt. On a double gate, the same gap is suggested.

As a general rule, a stile must be at least 4″ wide to work with a deadbolt. There needs to be enough wood on the outer edge of the hole to keep the structure intact. The image below shows a 4″ wide stile using a 2-3/8″ backset. That leaves 5/8″ of material.

This gate was built with 5-1/2" stiles, so the client chose a deadbolt with 2-3/4" backset to center it.

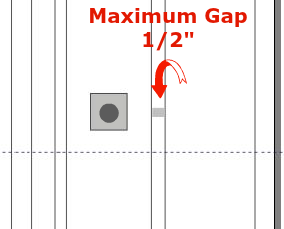

Mind the Gap

The gap between the gate and the post needs to be 1/2″ or less. When the bolt is “thrown” (locked) it extends 1″ out from the edge of the gate.

With a maximum gap of 1/2″, that leaves 1/2″ of the bolt to be engaged in the strike plate. The ideal gap is more like 1/4″ to 3/8″, which provides for even more engagement of the bolt. On a double gate, the same gap is suggested.

Special Circumstances

What if you don’t have the door style of gate construction? Continue reading below for photos and discussions of how to approach different gate setups.

2x4 or 2x6 On-Edge Construction

(FAR LEFT) This client built his gate out of 2×4 material set on edge. On the interior of the gate, he needed to build up the thickness in order to have a flush surface to install the deadbolt to. He created a block and affixed it to the 2×4 frame, then followed up with a regular installation of a stainless steel round deadbolt and Elise Latch (both discontinued).

(LEFT) The gate above was built of 2x6's. The same method of blocking was used (no deadbolt on this gate).

Horizontal Gates

With a horizontal gate, whatever the framing inside or behind the horizontal slats, you’ll need to ‘block’ an area (similar to photo to the right) to create a solid element for the deadbolt to be installed to. A block would be a solid piece of wood fastened to the frame of the gate. Most often it’s hidden from view by the horizontal slats.

Metal Gates

On metal gates, you need to incorporate a lock box into the structure – a lock box is a metal box, the same thickness as the gate, that has the holes pre-made to take a deadbolt and/or leverset installation. Metal fabricators are familiar with these and can either build one for you, or can source an off-the-shelf lock box.

What You Can Expect From A Deadbolt on a Gate

While the exterior plates of your deadbolt may be bronze or stainless steel, the interior mechanism is steel. We don’t know of any deadbolt mechanism on the market that is made of anything but steel. It’s important to manage expectations about what deadbolts used on gates can require. Regular maintenance will help the deadbolt keep working for the long term.

Rust + Maintenance

In order to maintain the surface of your deadbolt trim plates, periodic washing with a gentle dish soap will help. We recommend Dawn or Joy (original blue formula, not anti-bacterial). Dip a clean soft cloth in sudsy water, wipe the deadbolt plates to rid them of salt or dirt depositions, and then wipe again with a clean wet cloth. Dry with a separate cloth.

Depending on your location (coastal or not), we’d recommend 1-2 times a year. For the internal components, the best option is to keep the parts lubricated. To do this, you’d remove the interior trim plate and apply a lubricant. Expect to replace the bolt backset every 2-5 years.

Security

Deadbolts on a gate provide a deterrent to access, but they are not secure in the same way a door is. We have heard client stories of various ways that criminals have bypassed a deadbolt. Gates are different than doors because they’ve got a gap below and are open above.

Alternatives to Deadbolts

You've made it to the end this page and you're thinking a deadbolt might not be worth the trouble? Gate structure won't allow a deadbolt to work? Here are some options for you to consider.

This bronze flip latch has a spot for a padlock to slide through.

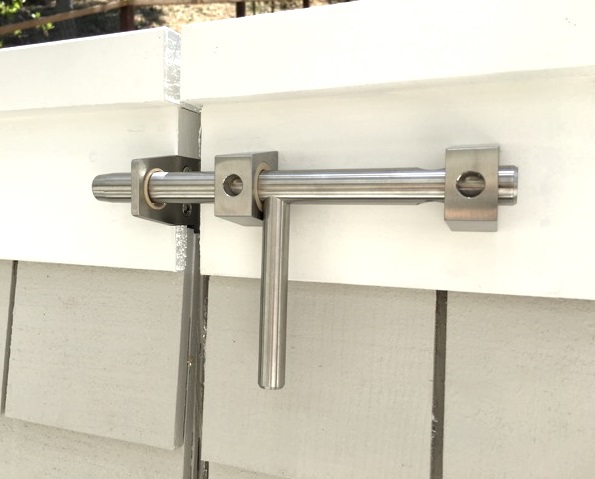

Marine Grade Stainless Slide Bolt. Padlock fits in the bolt to lock it in place.

This rim lock requires only a 1" thru-hole.

Note: we don't carry this.